Servo Motor Types, Construction, Working, Controlling & Applications

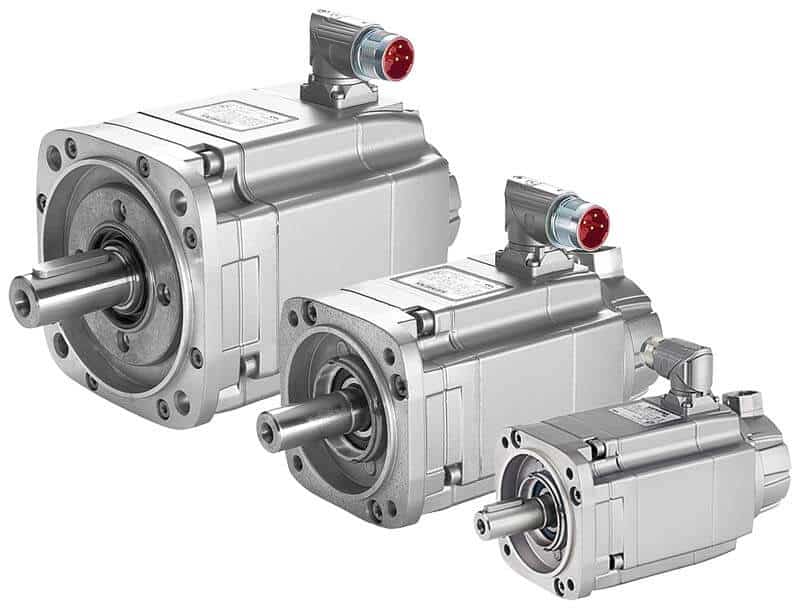

The servo motor is the motor used for servo system. The so-called servo system is a control system that acts according to the instructions. It can compare the actual state of the system with the corresponding state of the instructions, and use the comparison result for further control. Servo motors include direct current motors (with brush and.

What is a Servo Motor and How it Works? YouTube

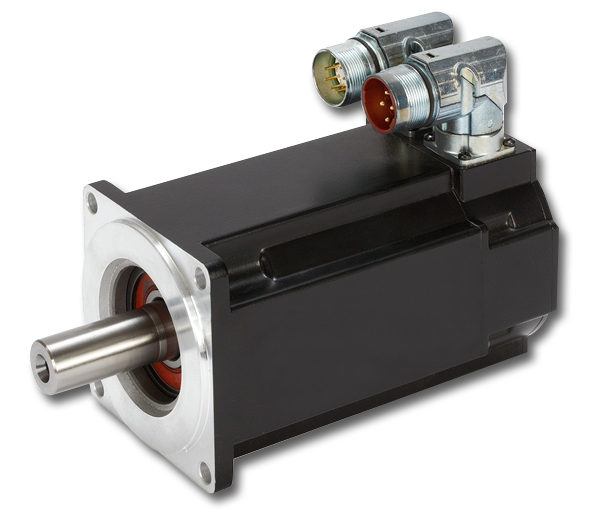

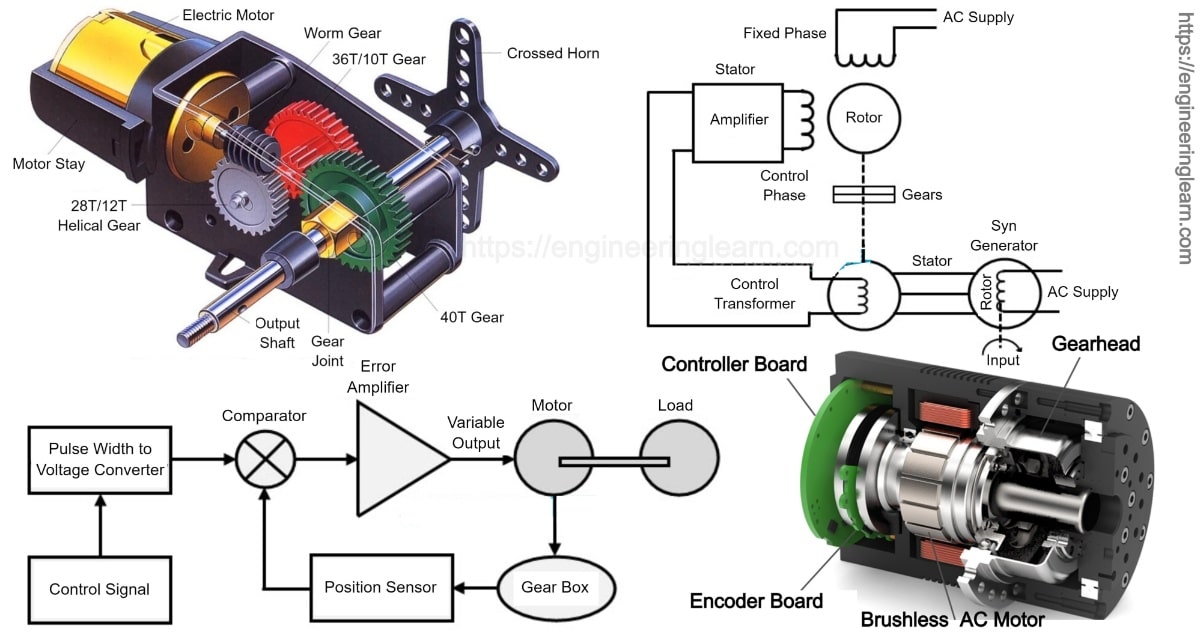

A servo motor is a rotary or linear actuator that allows for precise control of angular position. It consists of a motor coupled to a sensor for position feedback. It also requires a servo drive to complete the system. The drive uses the feedback sensor to precisely control the position, speed or velocity of the motor. How Does a Servo Motor Work?

Motor Servo, Pengertian, Cara Kerja, Jenis, dan Pengaplikasiannya

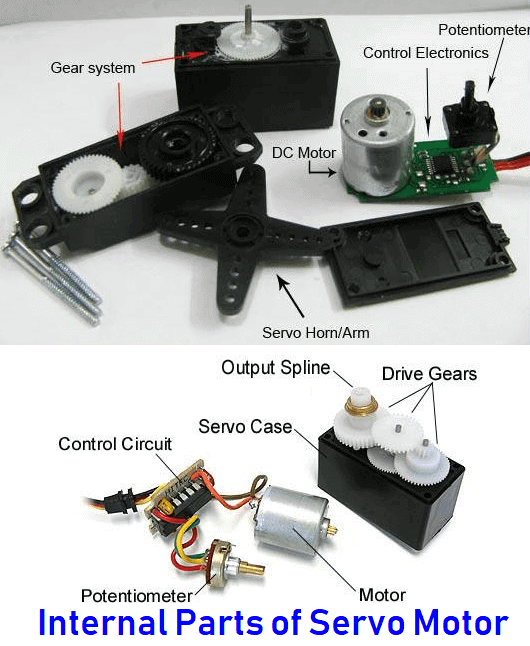

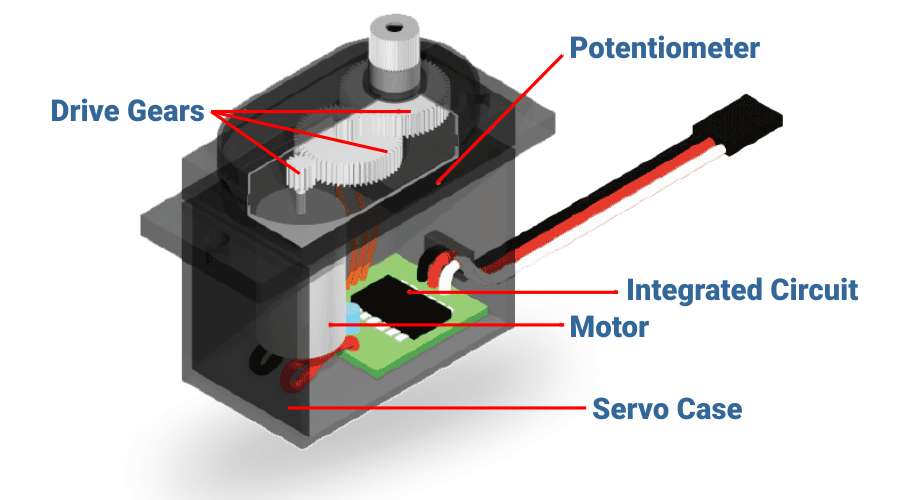

A servomotor is a structural unit of a servo system and is used with a servo drive. The servomotor includes the motor that drives the load and a position detection component, such as an encoder.

Servo Motor What type of motor is it? AC or DC, brushed or brushless....

The servo motor is an electric motor, which enables continuous determination of precise positions, speeds and torque via control electronics (servo controller).

What is a servo motor? How it works & application

A servo motor is a motor that rotates with a high degree of precision. Servo motors frequently have a control circuit that provides feedback on the present position of the motor shaft, allowing them to revolve with great precision. Servo motors are utilized in a variety of industries and offer a number of benefits, as we've already described.

How to Control Multiple Servo Motors with Arduino

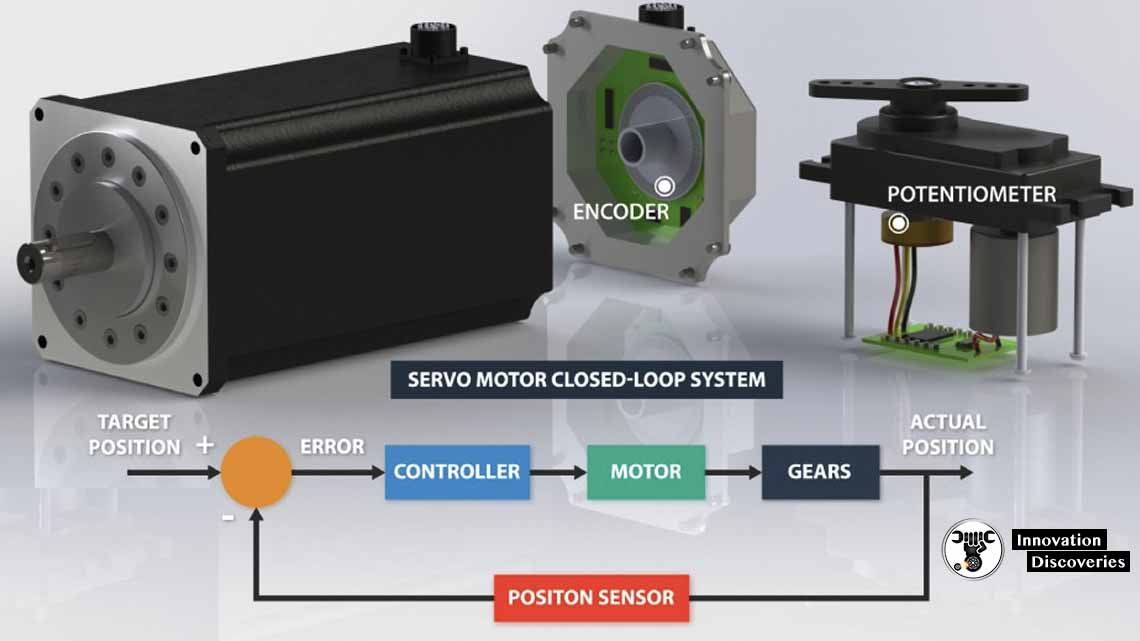

The servo motor is a closed-loop mechanism that incorporates positional feedback in order to control the rotational or linear speed and position. The motor is controlled with an electric signal, either analog or digital, which determines the amount of movement which represents the final command position for the shaft.

Difference between AC Servo Motor and DC Servo Motor Polytechnic Hub

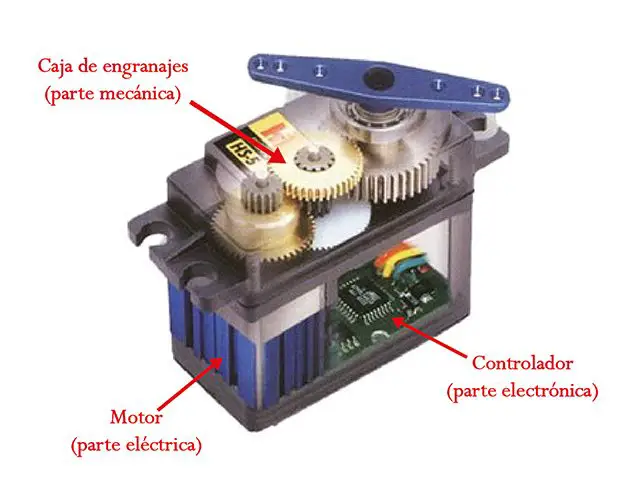

It converts electrical energy into mechanical energy. This type of motor is used for precise control, and we can connect different attachments to achieve that. We control the position of a servo motor using a controller. So, we often find it used in robotics, automation and even the steering for remote control cars.

Types of Servo Motors and Their Working Principles Linquip

A servomotor (or servo motor or simply servo) [1] is a rotary or linear actuator that allows for precise control of angular or linear position, velocity, and acceleration in a mechanical system. [1] [2] It constitutes part of a servomechanism, and consists of a suitable motor coupled to a sensor for position feedback.

Basics of Servo motor, it's advantages and disadvantages Electrical Industrial Automation

In mechanical and control engineering, a servomechanism (also called servo system, or simply servo) is a control system for the position and its time derivatives, such as velocity, of a mechanical system. It often includes a servomotor, and uses closed-loop control to reduce steady-state error and improve dynamic response. [1]

What is and how does a servomotor work? Panama Hitek

The term "servo" refers to the control mechanism. In terms of technology, the mechanism that performs control is called the "master" and the mechanism being controlled is called the "slave." Both terms, "servo" and "slave" derive from "servus", the Latin word for slave.

Servo motor basics. How to use servo motor YouTube

A servo motor is a type of motor that can rotate with great precision. Normally this type of motor consists of a control circuit that provides feedback on the current position of the motor shaft, this feedback allows the servo motors to rotate with great precision.

What is Servo Motor and its Types?

The servo motor can be rotated from 0 to 180 degrees, but up to 210 degrees depending on the manufacturer. This degree of rotation can be controlled by applying an electrical pulse of the appropriate width to its control pin. in every 20 milliseconds. 1 ms (1 millisecond) wide pulse can rotate the servo 0 degrees, 1.5 ms can rotate 90 degrees (neutral position) and 2 ms pulse can rotate 180.

Servo Motor Types, Construction, Working, Controlling & Applications

A servomotor (or servo motor) is a rotary or linear actuator that allows precise control of angular or linear position, velocity, and acceleration. It consists of a suitable motor coupled to a position feedback sensor. Servo motors are used in applications such as robotics, CNC machinery, or automated manufacturing.

Servomotor Working Principle Engineering Learner

noun ser· vo· mo· tor ˈsər-vō-ˌmō-tər : a power-driven mechanism that supplements a primary control operated by a comparatively feeble force (as in a servomechanism) Examples of servomotor in a Sentence Recent Examples on the Web Our test car also suffered from an incessantly whirring servomotor.

What is Servo Motor and How does it Work? Foreign Policy

A servo motor is a rotary actuator or motor that allows for a precise control in terms of angular position, acceleration and velocity, capabilities that a regular motor does not have. It makes use of a regular motor and pairs it with a sensor for position feedback.

What is Servo Motor Advantages, Disadvantages Applications Robu.in

Definition of Servo Motor: A servo motor is defined as a linear or rotary type of actuator that provides fast precision position control for closed-loop position control applications. As compared to large industrial electric motors, servo motors are not useful for continuous energy conversion.