How Much Cement Is In A Cubic Metre Of Concrete

The RCC concrete mix ratio for this strength of concrete is design mix. Compressive strength: 20 Mpa, 4350 psi. Uses: M30 concrete is also used in RCC construction for slabs, beams, footings and columns for structures that are slightly heavier. As this grade of concrete is more durable than the lowest grade concrete mix, it can also be used for.

Kolik cementu, písku a kameniva je potřeba pro beton M25, M20, M15, M10 a M7,5 beton

C20, C25 and C30 grade of concrete used in all structural work of building construction in RCC beam, column, Foundation,slab and in other RCC structure.. C20/25 concrete mix ratio. C20/25 concrete grade has mix ratio of 1:1:2 (1 cement : 1 Sand : 2 Stone). This means, 1 bucket of Portland cement mixed with 1 buckets of Sand and 2 buckets of.

Habituer Submergé de plus en plus what is a 1 2 3 mix for concrete Renard débat Spot de nuit

Concrete Mix Ratio: Max. size of aggregates (mm) Water for dry aggregates (liter)* Water for aggregates condition from dry to moist batch (liter)*. Mass concrete for heavy walls, lean concrete for levelling course of RCC foundations: 1:3:6: 63: 36: 30 to 32: Medium *for one cement bag batch.

Concrete Mix Ratio What Is It? What Is 123?And More. Handyman's World

What is the mix ratio of C20 concrete? The mix ratio of C20 concrete is typically 1:2:4. This means that for every part of cement, you would use two parts of sand and four parts of coarse aggregate. How much sand required for M20 concrete? The amount of sand required for M20 concrete depends on the mix ratio.

What is the strongest concrete mix ratio?

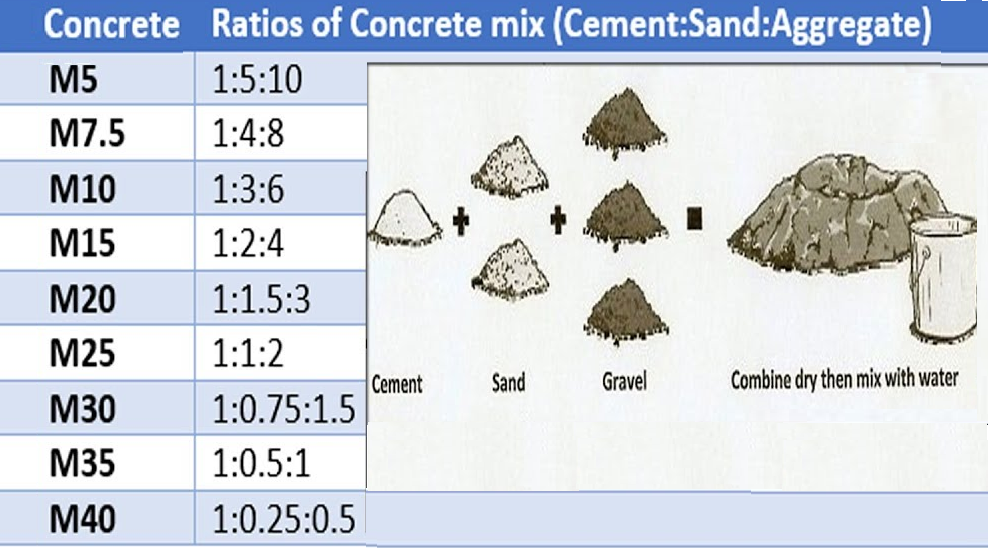

Concrete Mix Ratio. The concrete mix ratio is the proportion of its ingredients like cement, sand, aggregate, and water. These mix ratios are defined based on the type of construction and required strength.. M45 and M50 grades are used for RCC, Runways, Concrete Roads( POQ ) Prestressed concrete girders, RCC columns, Prestressed beams etc.

Civil Engineering Handbook, Civil Engineering Books, Engineering Notes, Civil Engineering

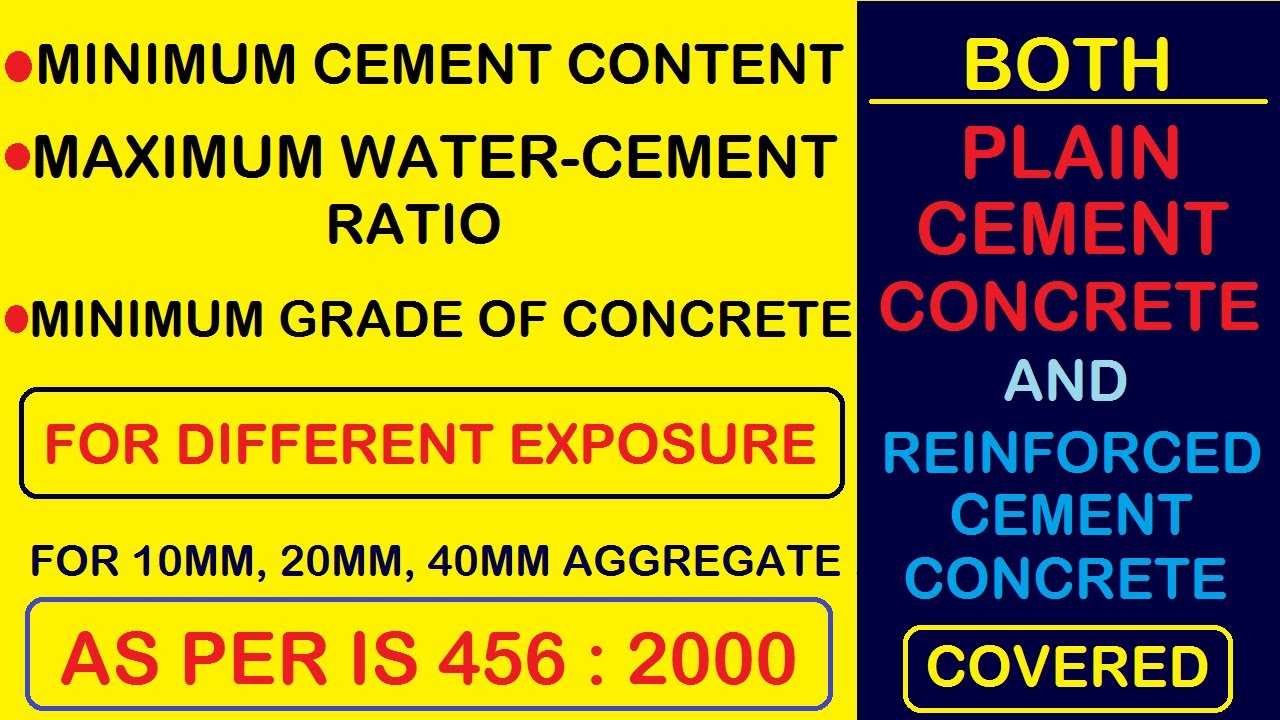

Proper mixture proportioning is crucial in creating a high-performing RCC mixture for an RCC Pavement. There are a number of factors that should be considered when designing an RCC mixture and they include constructability, mechanical strength, economics, durability and performance. There are two general approaches to mixture proportioning.

CONCRETE MIX DESIGN OF M25 GRADE AS PER IS 102622019 HIGHWAY GUIDE

Reinforced concrete is a mixture of cement, water, and aggregates, with the addition of steel reinforcement to provide additional strength and durability. 2. Mixing ratio and proportions. The standard mixing ratio for reinforced concrete is 1:2:3:0.4, which means one part cement, two parts sand, three parts gravel or crushed stone, and 0.4.

Civil Engineering Handbook, Engineering Notes, Civil Engineering Design, Mechanical Engineering

These types of concrete mix ratios are discussed in this article. Types of Concrete Mix Ratio - Mix Designs Nominal Concrete Mix Ratios In the past the specifications for concrete prescribed the proportions of cement, fine and coarse aggregates. These mixes of fixed cement-aggregate ratio which ensures adequate strength are termed nominal mixes.

Concrete Mix Ratio What Is It? What Is 123?And More. Handyman's World

The concrete mix ratio for RCC (Reinforced Cement Concrete) columns typically ranges from 1:1.5:3 to 1:1:2, where the first number represents the proportion of cement, the second number is for sand, and the third number is for coarse aggregate.

[最新] 2×4×8 2558282 4 8 16 zahlenfolge Saejospictabmsj

The best concrete mix ratio for RCC column (reinforced column) is 1:1.5:3, (one part cement mix to 1.5 parts sand and 3 parts aggregate). As we know that column is RCC structure, so we can use minimum grade of M20 grade and concrete mix ratio 1:1.5:3 for column & maximum grade of concrete m25, M30 and much higher are used as per design for.

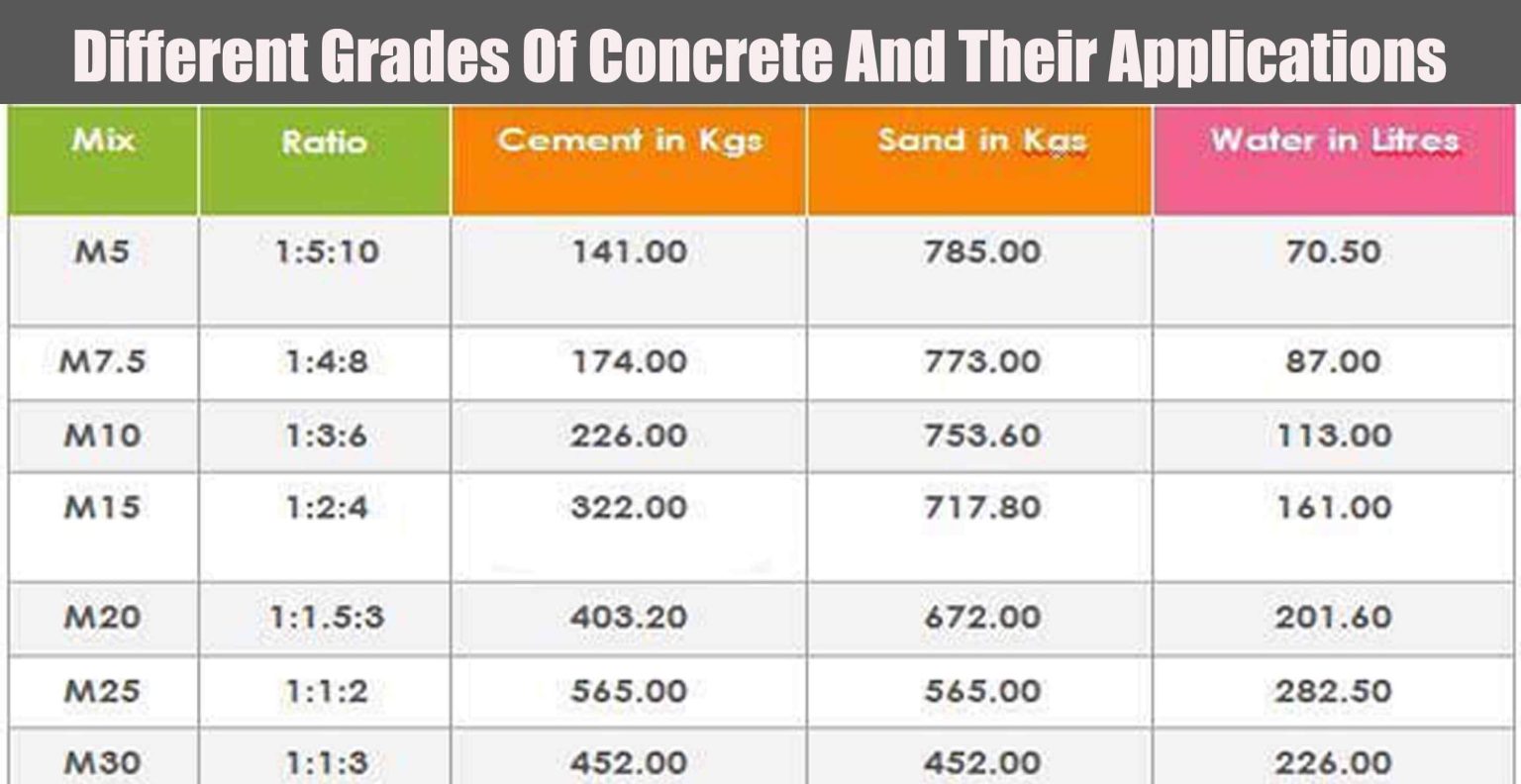

Different Grades Of Concrete And Their Applications Engineering Discoveries

We'll go into the ins and outs of mix ratios in more detail below, but to simplify, a good concrete mix ratio for a concrete floor is: 1: cement 2: sand 4: coarse aggregates (for concrete slabs) When mixing, it's important that the concrete is placed within half an hour to ensure consistency and easy placement.

Min Cement Content Max W/C Ratio Min Concrete Grade for Diff Exposure for PCC & RCC By L & T

Concrete Mix Ratio. To make concrete, you'll need four basic ingredients: cement, sand, aggregate, water, and additional mix. Concrete mix design is the method of determining the correct proportions of cement, fine aggregate (sand), and aggregates for concrete to achieve the target strength of the prepared concrete mix.. The advantage of the Concrete Mixture Design is that it gives the.

Share more than 138 water per bag of concrete super hot esthdonghoadian

Concrete Grade Mix Ratio Characteristic Compressive Strength Fck at 28 days MPa(N/mm2) Characteristic Compressive Strength Fck at 28 days MPa(psi) M50: Design Mix: 50 MPa:. While M20 grade concrete is used for RCC works (for mild exposure) such as the construction of slabs, beams, columns, footings, etc. 2. Standard Grade:

concrete mix ratio for slab, As Simple 123 Concrete

Concrete Mix Ratio for a C20 and C20P (Portland) Mix. The proportions of materials for a C20 and C20P (P = Portland cement) concrete mix are: 1 part cement; 2 parts fine aggregate (sand) 4 parts coarse aggregate; If you are using premixed ballast, then: 6 parts pre mixed ballast;

How to design m30 concrete by is 10262 using 10 MM down course aggregate Quora

Some basic mixing ratios for concrete are 1:2:3, 1:3:3, 1:2:4. These mixing ratios are based on the proportions of cement : sand : stone in that order. The ratio you use will depend on what psi strength you need. a good mixture for concrete has 4 basic ingredients.

12.RCC. Concrete Mix Types Of Concrete Mix Nominal And Design Mix How To Do Mix Of

The strength of RCC is a function of w/c ratio only for mixture with Vebe time of ~ 15 to 20 sec. range. For drier mix, the strength is more controlled by the moisture-density relationship. If water content is less than optimum => voids in structure, poorly compacted concrete with loss in density and strengths.